OEM certification equips collision repair technicians with advanced training in factory standard repairs, including CAD and robotic systems. This rigorous process ensures precise, safe, and high-quality auto body work, managing complex scenarios and sustainable practices for diverse vehicle makes and models. Hands-on training in panel replacement, structural repair, and painting is vital for mastering these factory standard repair techniques.

In today’s automotive industry, Original Equipment Manufacturer (OEM) certified collision repair technicians are indispensable. To ensure top-tier vehicle restoration, these professionals must meet stringent OEM certification standards. This article explores the crucial training requirements for these specialists, focusing on understanding OEM criteria, essential skillsets, and hands-on practice. By delving into these key areas, technicians can master factory standard repairs, guaranteeing exceptional quality and customer satisfaction.

- Understanding OEM Certification Standards for Collision Repair

- Essential Training Components for Factory Standard Repairs

- Hands-On Training: Mastering Techniques for Quality Assurance

Understanding OEM Certification Standards for Collision Repair

OEM (Original Equipment Manufacturer) certification for collision repair technicians sets a high standard for auto body shops and auto repair services. This rigorous process ensures that repairs are done to factory specifications, maintaining the vehicle’s original quality and safety standards. Understanding these requirements is crucial for any auto body shop aiming to offer superior auto body repairs while adhering to industry best practices.

The certification process involves comprehensive training on the specific make and model of vehicles, focusing on intricate details such as panel fitting, paint technology, and structural integrity. Technicians learn about advanced tools and techniques used by manufacturers, enabling them to perform precise auto repair services. This includes mastering computer-aided design (CAD) systems for accurate measurements and understanding complex manufacturing processes, ensuring every repair matches the factory standard repair.

Essential Training Components for Factory Standard Repairs

In the pursuit of achieving factory standard repairs, OEM (Original Equipment Manufacturer) certified collision repair technicians must undergo comprehensive training that covers a multitude of essential components. This rigorous education is pivotal in ensuring that repairs not only meet but exceed the stringent quality benchmarks set by automobile manufacturers. The core curriculum should encompass a deep dive into various techniques specific to auto body repair and dent repair, empowering technicians with the skills to handle complex scenarios effectively. Hands-on training in car paint services, including color matching and application, is another critical aspect that allows professionals to deliver flawless finishes.

Moreover, exposure to advanced tools and equipment designed for precision work is vital. Technicians must be adept at using modern technology like computer-aided design (CAD) software for accurate measurements and planning, as well as robotic welding systems for consistent, high-quality joins. Safety protocols and environmental considerations also form a significant part of the training, emphasizing the importance of sustainable practices in auto body repair while ensuring the well-being of technicians and workplace safety.

Hands-On Training: Mastering Techniques for Quality Assurance

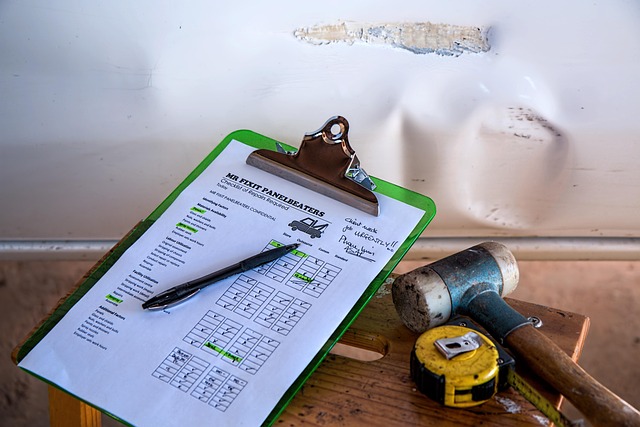

Mastering the art of collision repair requires a significant amount of hands-on training. For OEM certified technicians, this involves learning and perfecting techniques that adhere to factory standard repair practices. By engaging in practical exercises, trainees develop their skills in areas such as panel replacement, structural repair, and painting. This immersive experience is crucial for ensuring the quality and safety of repairs, especially when dealing with complex car dent removal or more specialized tasks like paintless dent repair.

The training should equip technicians with the knowledge to handle various types of damage encountered in a collision repair shop. Through rigorous practice, they learn to assess each situation uniquely, applying the most suitable methods for both aesthetic and structural restoration. This holistic approach to learning ensures that certified technicians are well-prepared to tackle any challenge, delivering top-notch results in every paintless dent repair or more conventional car dent removal process.

Training requirements for OEM certified collision repair technicians are crucial for ensuring high-quality, factory standard repairs. By understanding the certification standards, engaging in comprehensive hands-on training, and mastering advanced techniques, technicians can deliver exceptional results that meet or exceed original equipment manufacturer expectations. This investment in education not only enhances customer satisfaction but also positions technicians as experts in their field, contributing to a robust automotive industry.